Use of test mandrels

In order to be able to determine whether the pressing of the valve, sleeve and hydraulic hose is correct and safe, so-called test mandrels are used to check the pressing dimension.

Only when the test mandrel “sticks” in the correct place when inserted into the hose nipple is the pressing dimension correct and the hydraulic hose line ready for safe installation.

How to correctly install a hose assembly, you will learn here.

When using test mandrels to ensure the pressing dimension, proceed as follows:

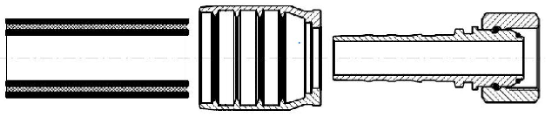

1. select the hose required for your requirements and the matching sockets and fittings from our product range.

Hose

Version

Fitting

2. cut the hose to the required length using an appropriate cutting machine.

3. if peeling of the hose is necessary, remove the upper rubber (for peeling dimensions, please refer to our pressing dimension tables) without damaging the steel core(s) of the hose.

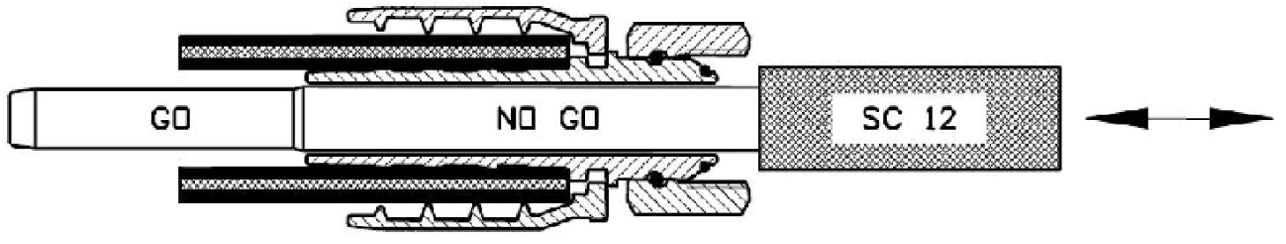

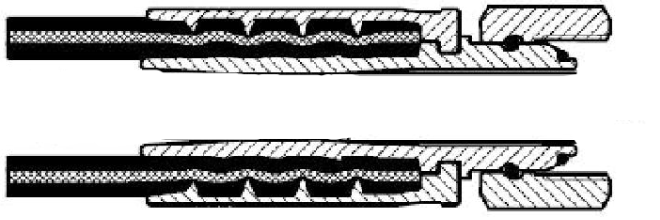

4. push the socket completely over the hose and push the fitting completely into the hose. Use a test mandrel of the appropriate nominal size of the valve and insert it into the valve. The test mandrel should be able to slide into the fitting as far as it will go before pressing.

Pull the test mandrel out of the hose again.

Test mandrel slips completely into the fitting:

Hose

Version

Fitting

Test mandrel

5. press the mount with the appropriate press dimension, which you can find on the corresponding press dimension table (for download in the download area).

6. check the pressing dimension first by measuring the outside of the socket. The measurements should correspond to the specific diameter with a tolerance of +0.0 / -0.2 mm. To do this, measure the diameter in the center of the socket between two opposing press jaw impressions.

Pressing dimension measuring point version

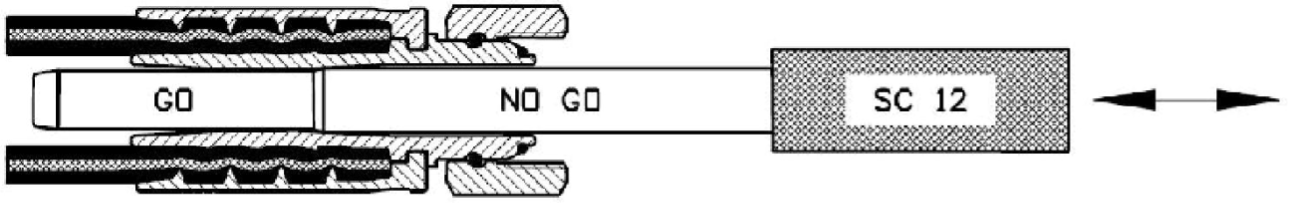

Now reinsert the test mandrel.

8. if the NO-GO area of the test mandrel gets stuck approximately in the middle of the hose nipple, as shown in the picture below, the pressing dimension is OK.

Optimal nipple constriction

9. if the NO-GO area of the test mandrel can still be pushed through the fitting as before pressing, reduce the pressing dimension in steps of 0.1 mm until an optimum nipple constriction (see picture above) is achieved.

We will help you!

Please do not hesitate to contact our experts in the office and in the field, who will be pleased to help you at any time with questions about press dimensions, correct fabrication and the use of test mandrels.

Our test mandrels in various nominal sizes and for different valve systems are available in our online store!